How can we help your business?

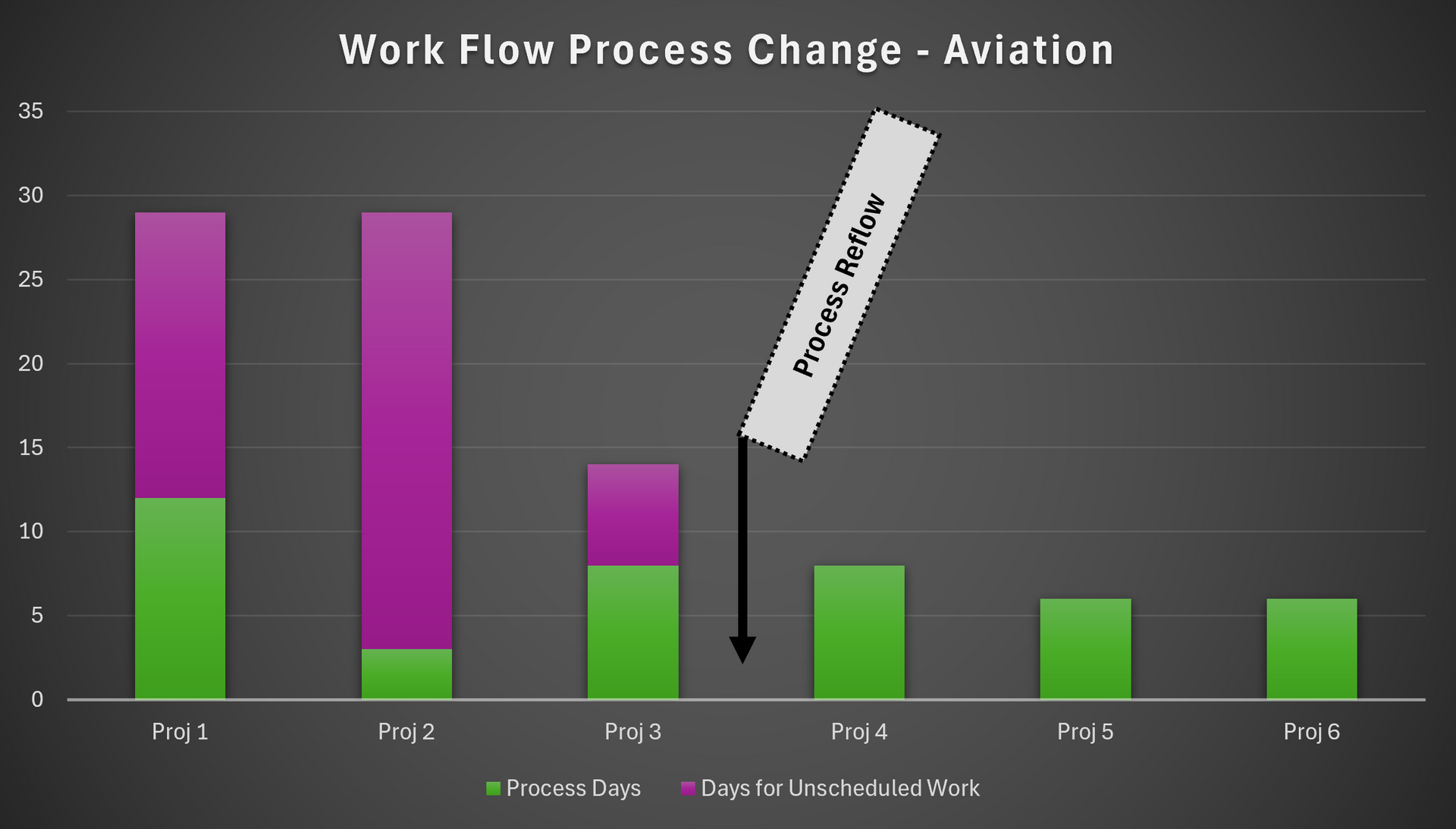

PROCESS SEQUENCING

Problem: All work was scheduled and completed simultaneously instead of in a deliberate sequence.

Solution: We outlined the process, prioritizing critical tasks early to avoid rework and identify major concerns first.

Impact: Reduced process days to stable level and mitigated unscheduled work to nonexistent levels as issues were

identified early and worked while the process completed.

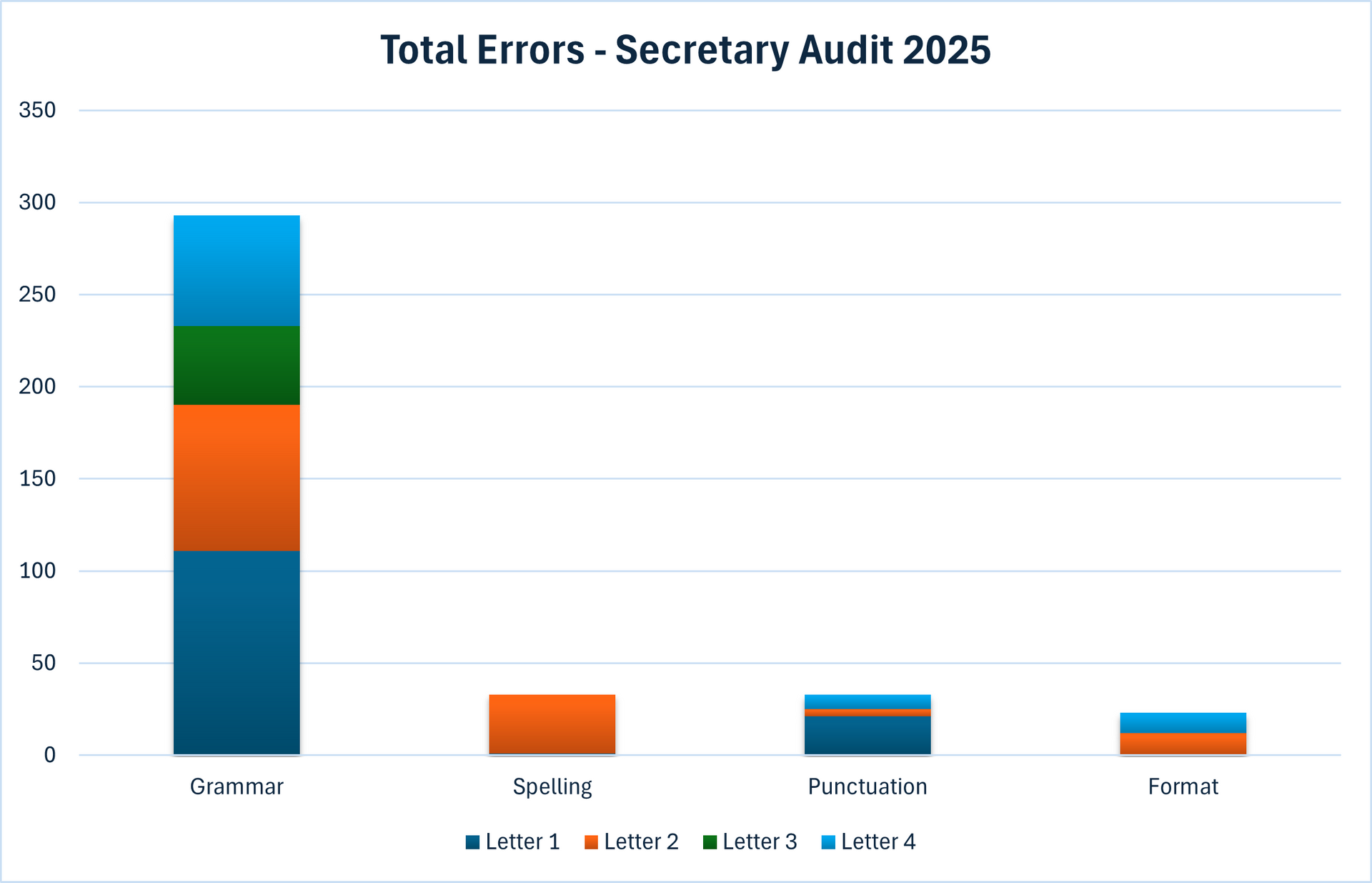

ANALYTICS OF QUALITY

Problem: A law firm had quality issues with their outgoing letters but didn’t know where or how to address the problem.

Solution: After two audits of small samples, errors were categorized to determine the most common issues.

Impact: Management took deliberate action working with their staff for grammatical errors, attacking the biggest problem first.

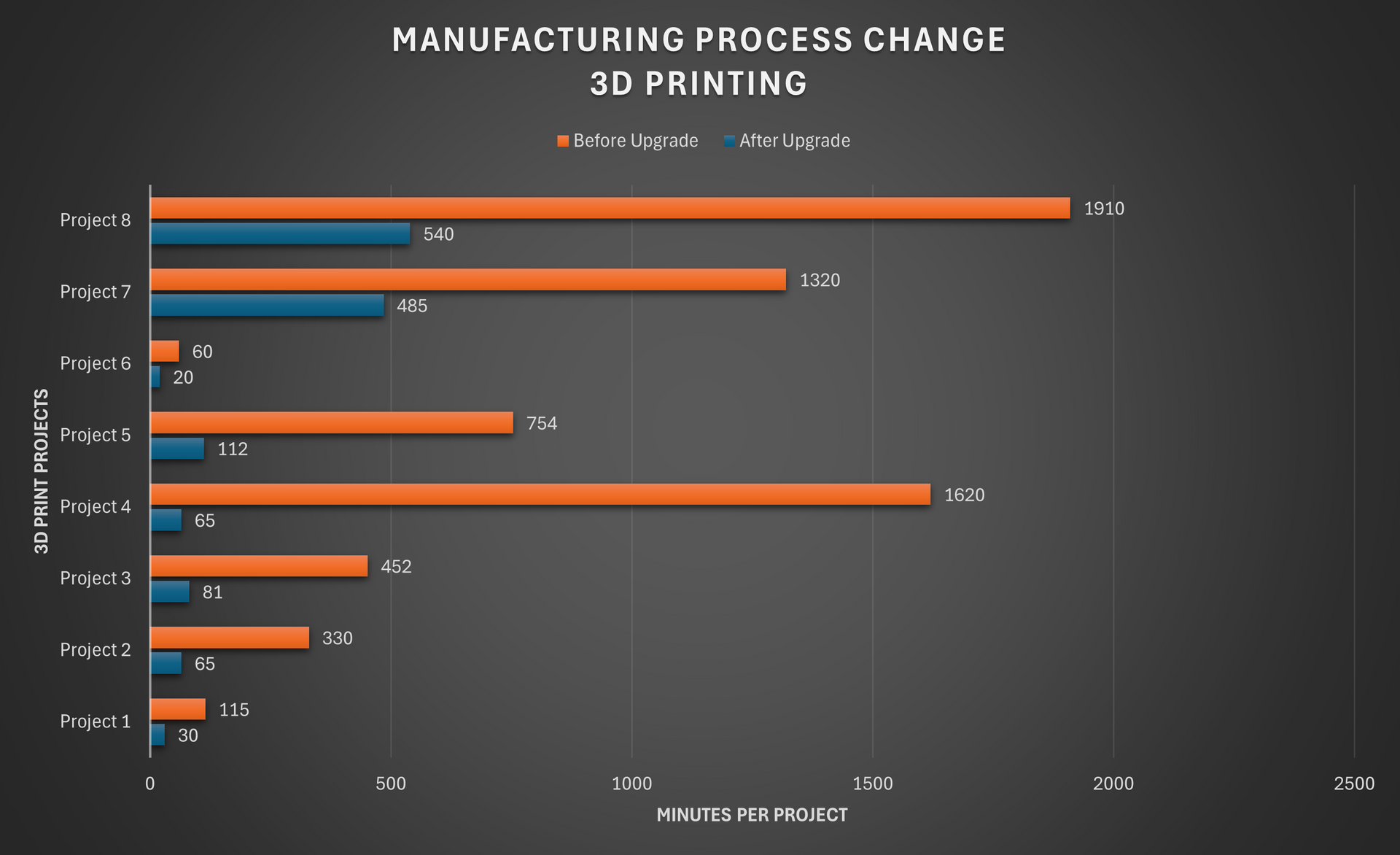

MANUFACTURING PROCESS

Problem: A 3D printer routinely malfunctioned, wasting material and time completing projects. We found the root cause to be contamination in the feeding line.

Solution: Replaced the unit with a closed loop system as the current system was outdated to current technology.

Impact:

Reduced project time by 78.7% and material waste by 43.7%, saving nearly $200 per project. The cost of the equipment upgrade was recovered within two months.

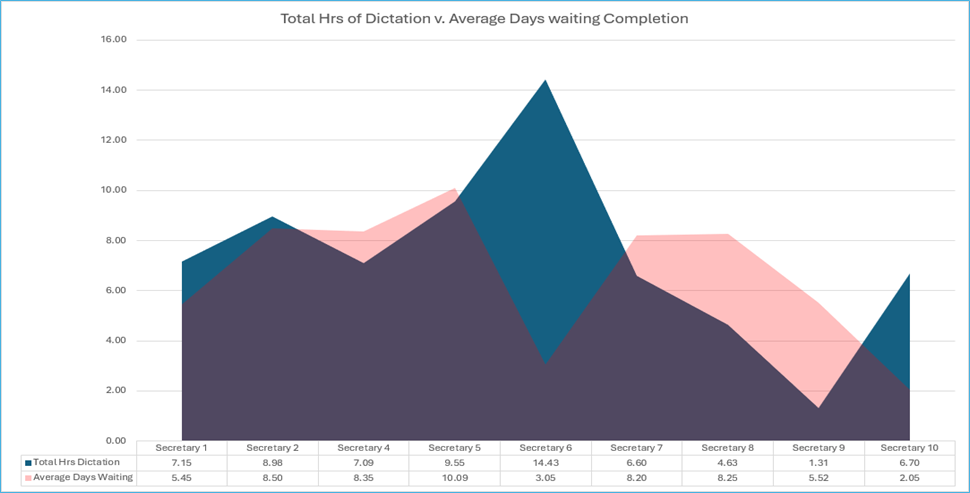

EFFICIENCY ASSESSMENT

Problem: A law firm had difficulty identifying how to determine bonuses and raises for staff.

Solution: Quantified efficiency of employees based on hours given to generate letters and days waiting completion.

Impact:

Company used quantifiable metrics to proportionately reward employees while also finding the best practices and other areas of improvement.